Five Must-See Machines At Fabtech

If you’ve ever been to Fabtech, you know that it can be overwhelming. With literally thousands of brands exhibiting, and quite possibly tens of thousands of machines on display, how do you decide what to make time to stop and see?

Luckily, our machine tool experts know what’s new and exciting at this year’s show, and we’re happy to help prioritize your trip through the aisles! Read on for five cool things to see at Fabtech 2018, and contact us to learn more about the innovative technology that will be on display at this year’s show.

Cidan’s New “Up-Down” Folder

Cidan’s New “Up-Down” Folder

If you’re looking for a press brake to form thinner metal, Cidan’s new FORMA-Z is a game-changer. It will form up to 11-gauge parts without flipping over the material. It’s innovative 8” tooling and 126” width can handle a variety of unwieldy sizes with ease, and it’s innovative two-way action means you won’t have to flip workpieces over during the forming process. Cidan’s unique press folds both up and down in order to save time and reduce manpower on large folding projects.

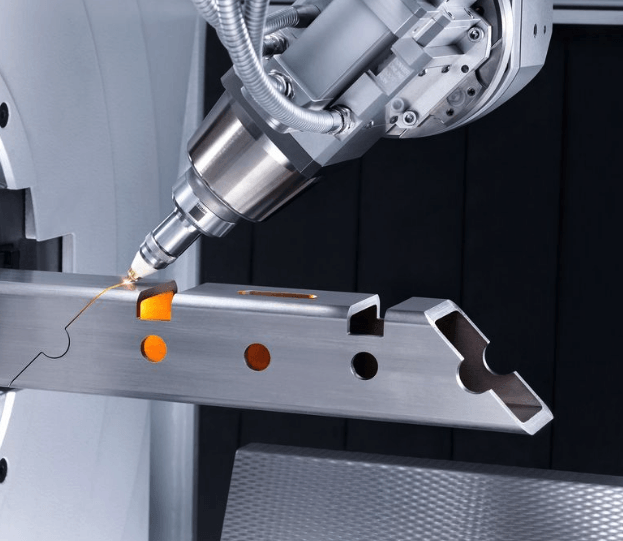

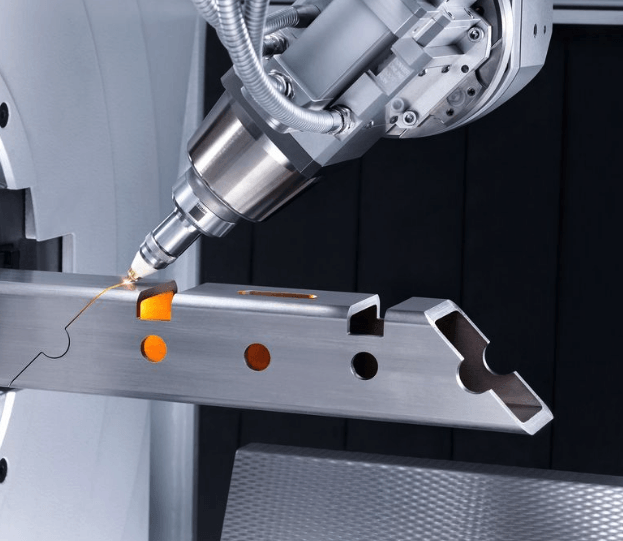

As a leader in laser cutting systems, TRUMPF’s newest and largest tube laser should come as no surprise. With the ability to handle tube up to 10” diameter, and up to .4” wall thickness, this is one major machine. Even better, with the addition of downstream processes such as drilling and tapping, plus automated part removal and sorting, TRUMPF engineers have designed a machine that will help you save time and money while cutting precision parts three shifts a day.

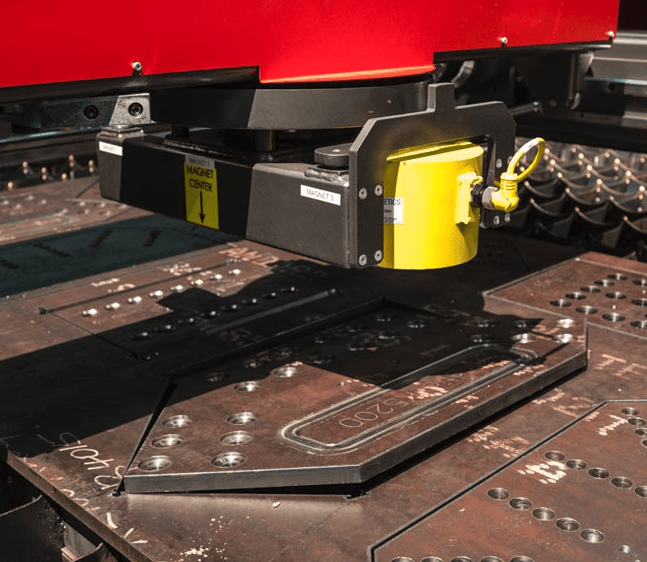

Integrated Sawing & Machining from Pat Mooney Saws

Pat Mooney is a leader in metal saw technology, and their newest machine, the PMI-CNC18MDS, adds powerful milling and drilling capabilities into the mix. With all-in-one sawing, milling and drilling, this machine will help fabricators do more with less, minimize WIP, and maximize part output.

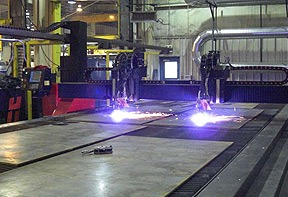

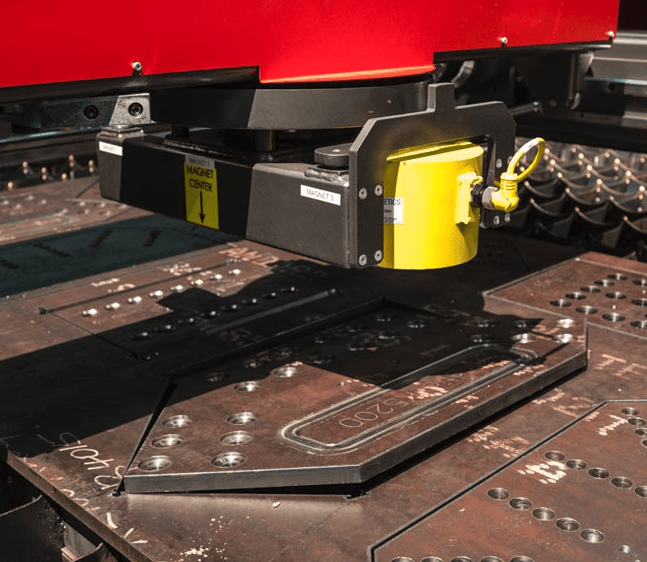

Increasing profitability is all about saving time, and Kinetic delivers. Their plasma cutting systems, with integrated milling and drilling, are renowned for helping fabricators maximize efficiency. Now, with the addition of automated part loading, you’ll be able to remove parts automatically while the machine keeps cutting, as well as sort and palletize by part number or work order number.

10HP Waterjet Cutting from OMAX

The leader in abrasive waterjet cutting is introducing their newest pump, an economical way to add waterjet capabilities to just about any shop. With 10HP of pumping power paired with a GlobalMAX table, this new system can cut metal up to 5” thick. And with a starting price much lower than more powerful systems, this new technology will help bring legendary OMAX capabilities to a wider array of businesses.

Want To Meet At The Show?

If you’ll be attending Fabtech this year, and you’re interested in learning more about any of the brands mentioned above, let’s meet at the show. Contact us today to let us know that you’ll be in attendance, and one of our fabrication experts will reach out to schedule a meeting. We’ll have our entire team at the show, and we’ll be happy to answer all of your questions and help you choose the best machine for your unique needs at this year’s Fabtech!