Messer Model Edgemax High Definition 8×24 w/400 amp power supply w/ 2017 control upgrade, New 2008

The EdgeMax P Dual X Drive cutting machine includes the following:

● The machine Gantry utilizes special aluminum extrusions to provide a light but extremely rigid

structure.

● The machine is driven by backlash free rack and pinion drives in both axes providing excellent

motion control required for precision plasma systems.

● EdgeMax P is driven by 600 watt AC servo motors coupled to precision planetary gear reducers

producing an accuracy of +\- .008” in any 72” move and repeatability of .004”.

● Travel speeds are up to 1200 inches per minute, increasing your productivity.

● The machine base is completely unitized with EZ Clean side gates providing lost part and quick

slag removal without removing slat frames.

● Special table surface skirts aid in smoke extraction and serve as slat retainers to prevent

slats from moving when magnetic lifting equipment is used to load/unload table.

● Heavy duty slat frame package (slats, slat frames, shielding)

● A smoke removal system including a longitudinal duct built into a side wall, cross plates to

divide the table into 32” long zones, and damper doors, one for each zone, which is actuated by the

cutti ng machine. Only one or two doors are open at any time to exhaust smoke surface.

● Table capacity of 3” thick material

8 Feet cutting width

24 Feet effective cut length

Laser pointer

● The laser pointer is used by the operator to physically identify the edge of a plate by

locating two (2) points along the edge

● The operator activates the plate alignment routine (part program rotation). Once activated,

the entire part program is offset (rotated), to the actual plate radial position.

● Then, the part program can be activated to cut the part or nest, as if the plate were square

to the machine axis.

● This feature simplifies set-up, reduces cycle time and eliminates scrap.

Control

● Windows 7 Professional (32 bit)

● 15” LED color touch screen

● > Intel 1.9 GHz, 2 cores

● > 2 GB DDR3 – Ram

● 2.5”, 320 GB SATA hard drive

● Two USB ports

● EtherCAT I/O bus communication system

● 10/100/1000 MBaud Ethernet port

Globals Control Cooler

● Provides effective cooling above 105° F ambient

● Cables with connectors required to interface.

● One extension panel with joystick and feed overide pot. Control including:

● cables with connectors required to interface.

Plasma Equipment:

One (1) Kaliburn Spirit400a Plasma System with Automatic Gas Console

● Precision, high density plasma system with a maximum output of 400A

● Rated for up to 2” production cutti ng of mild steel, 1 ½” stainless steel and aluminum

● All plasma process data can be remotely set by the operator at the Global Control via a serial

link to the automatic gas console and plasma power supply. This means all parameters are

controlled by the exclusive Messer database in the Global Control including remote on/off of the

power supply.

● Easily switch between cutti ng and marking using the same consumables via the part program.

Argon/Hydrogen manifold for Kaliburn Spirit 400a

Messer OL100s Plasma Lifter

● Increased part accuracy as a result of accurate height sensing

● Precision ball screw and dual linear guides provide a smooth and rigid platform for vertical

positioning of the cutti ng or marking tool

● 300” per minute vertical speed minimizes non-productive time

● Sealed bearings are virtually maintenance-free

● Magnetic collision sensor protects the torch while cutti ng from damage due to obstructions

Plasma station outlet equipment

● Station outlet consists of pre assembled piping with regulators for selected plasma gases.

The appropriate fitti ngs are attached to the outlet side to mate with the Messer supplied hoses

● Station outlet to be mounted in close proximity to the “x” axis powertrack entry point

● The customer is responsible for the piping to the inlet side of each station outlet assembly.

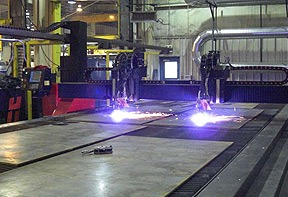

Photos