tube and pipe cutting

TUBE LASERS

With the high-precision and cleaner processing of lasers you can replace many of the conventional machining processes such as milling, sawing, punching, or deburring. And can even allow you to program in connections to aid in welding and limit inaccuracy.

When looking for a machine tool to process tubes, the choices are clear – if a tube laser can work for your application… go with it! You’ll get unmatched precision and the upmost flexibility to cut complex contours

trumpf tube laser, part connection example

TRUMPF TRULASER TUBE 3000 FIBER

The worthwhile laser tube cutting machine: the TruLaser Tube 3000 fiber is economical even when it is not being fully utilized. Thanks to its reliability and easy of operation, it is perfect for first-time users or as a supplementary machine.

TRUMPF trulaser tube 5000 fiber

The TruLaser Tube 5000 fiber achieves record speeds. It takes full advantage of the strengths of solid-state lasers. For the user, this means short processing times and a wide range of possible parts.

TRUMPF trulaser tube 7000 fiber

Built for maximum productivity, even for XXL tubes. With its robust solid-state laser, this machine can be used in numerous ways for the processing of tubes and profiles with a wide range of types of material and wall thicknesses.

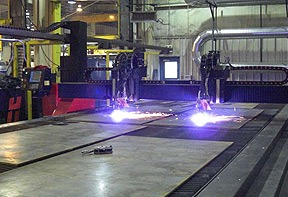

plasma tube cutting

When it comes to cutting thicker profiles, plasma is the way to go. The maximum thickness tolerance for processing is often times much higher than with lasers.

For those not needing the complete precision and are looking for more economical choices, plasma is a great option.

xr12 cnc rotary tube and pipe cutter

The XR12 gives the customer versatility to plasma cut tubing, pipe, square, rectangle, channel, and angle iron. Also, allows the routing of materials such as carbon steel, aluminum, wood, plastic, and pvc.

dragon a400

The Dragon A400 CNC tube and pipe plasma cutter easily marks and engraves on tube and pipe to make CAD/CAM designs a reality. Fabricate any design with holes and end cuts. Mark all bending locations, rotations, and degrees on the tube. Time-saving tool for tube and pipe processes