Quality built-to-last

What started out in 1904 with product line of belt sanders, mortisers, and bandsaws has grown into cutting-edge press brakes, hydraulic shears, mechanical shears, and fiber lasers. Wysong is known throughout North America as being among the most durable machines on the market.

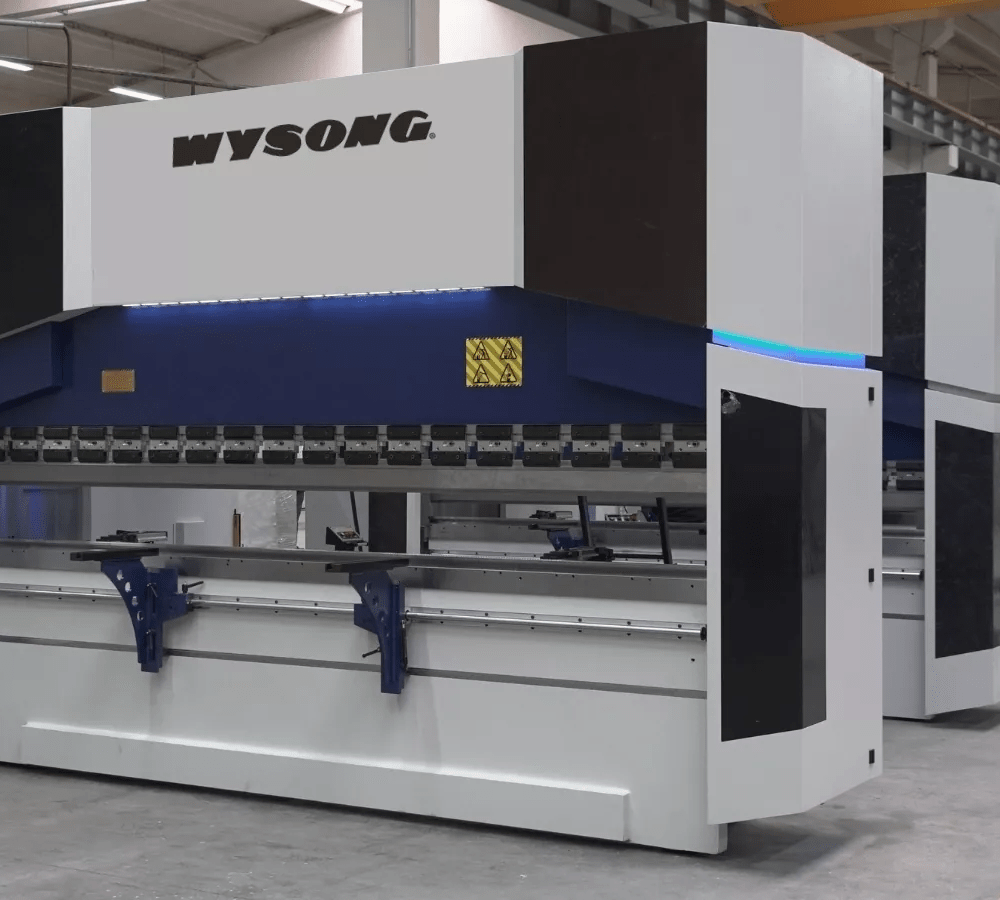

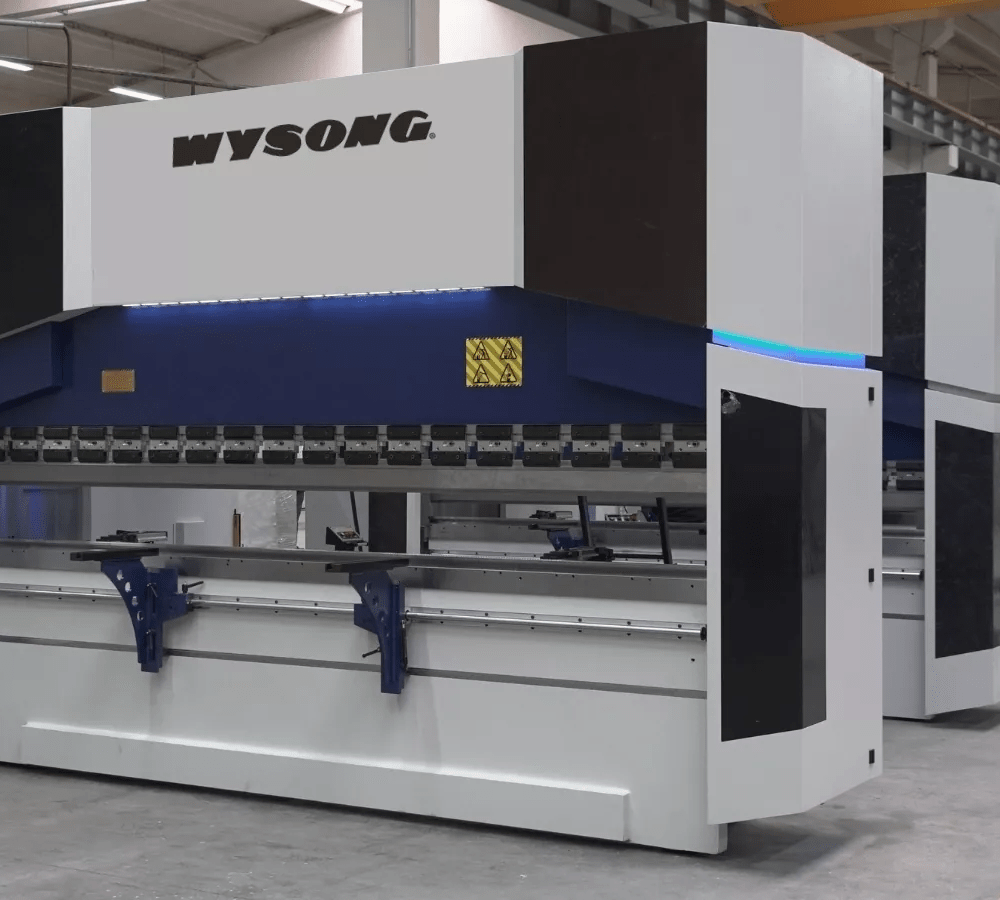

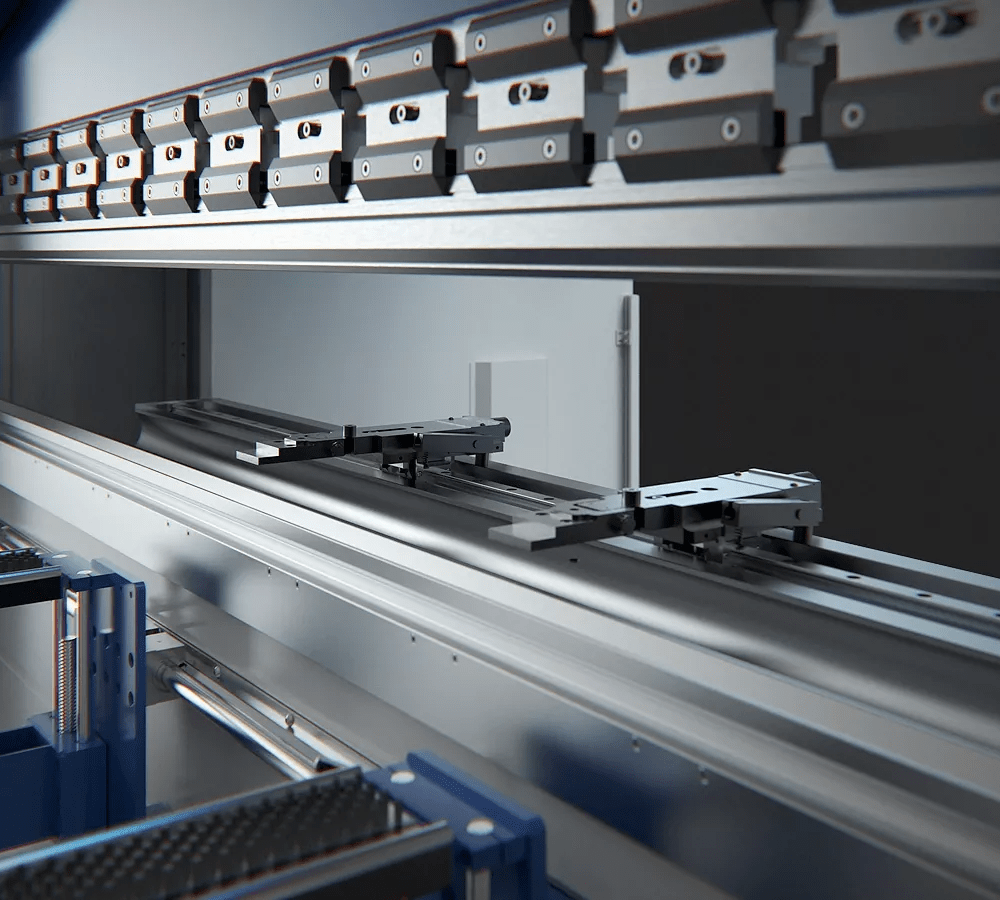

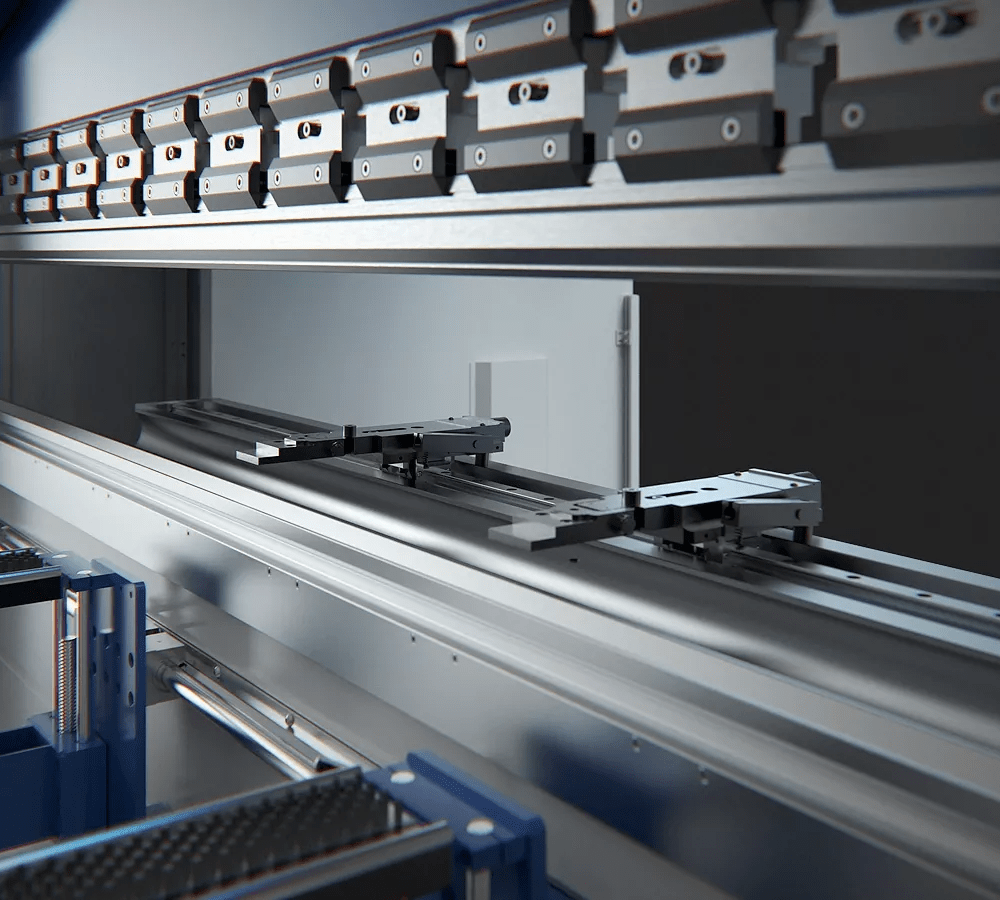

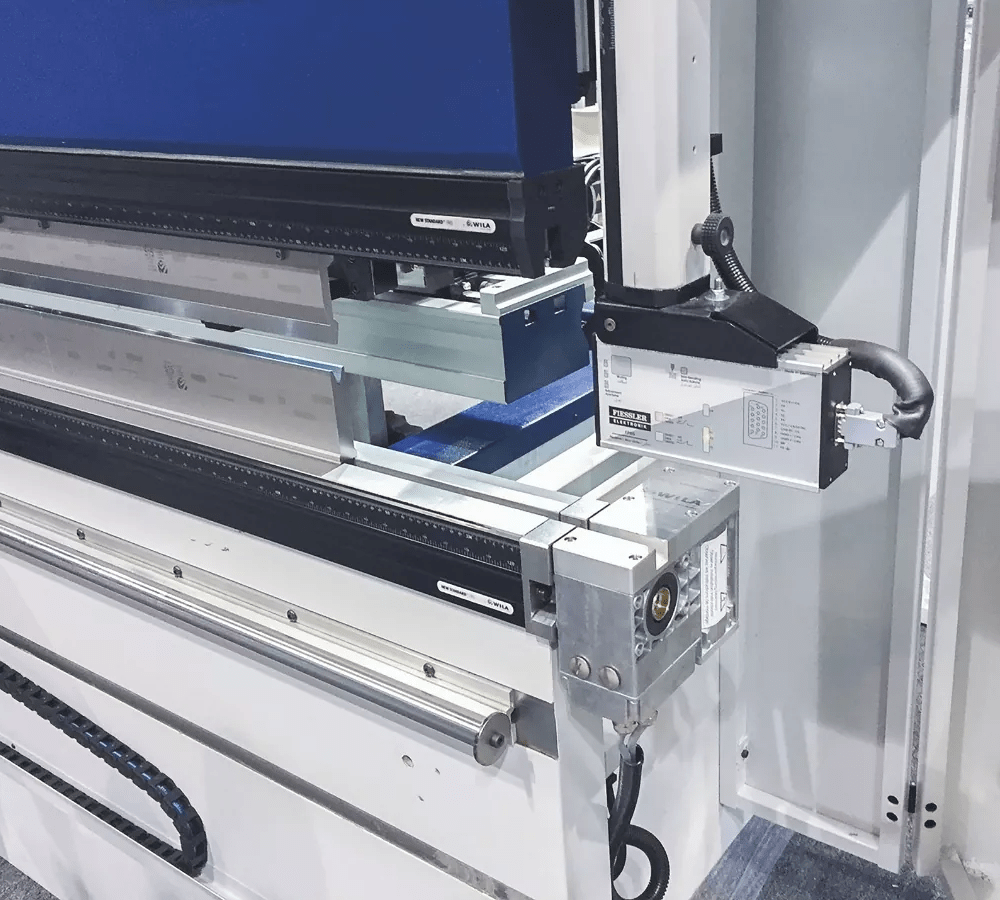

Press Brakes

Wysong Hydraulic Press Brakes are engineered to stand up to the most demanding production environments on the planet. Manufactured in Europe and supported by their industry veterans in the United States.

Standard Features Include:

- Delem Touch Screen Control

- Y1,Y2,X,R CNC 4 Axes

- 310mm Stroke, 410mm Throat Depth

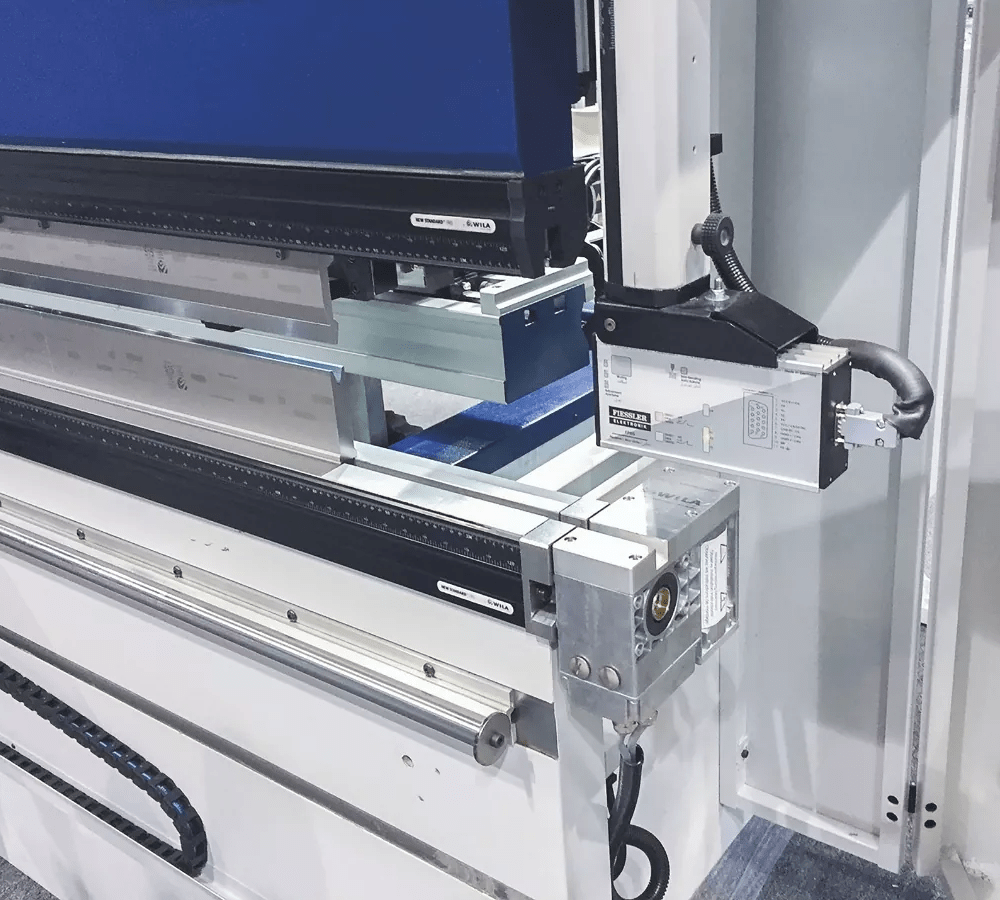

- ± 0,03 accuracy SERVO motorized back gauge. X=750mm, R=250mm

- Quick clamp Promecam punch tool holder

- Sliding front sheet support arms

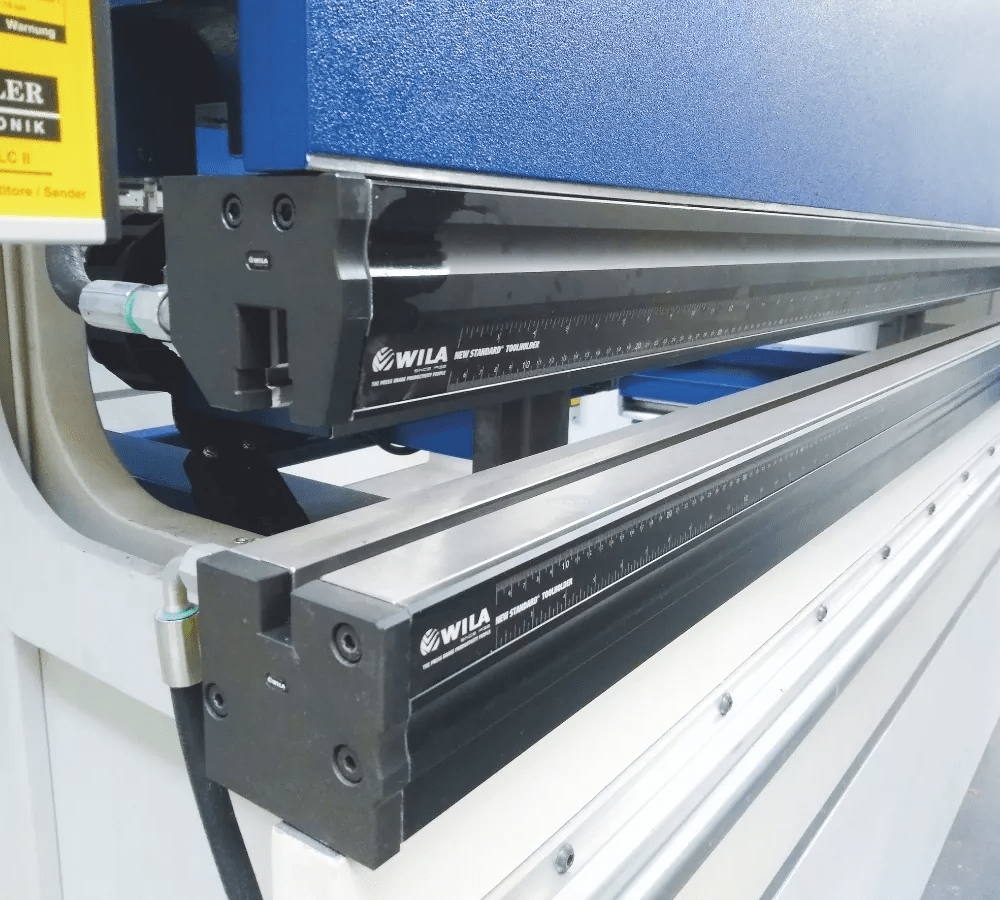

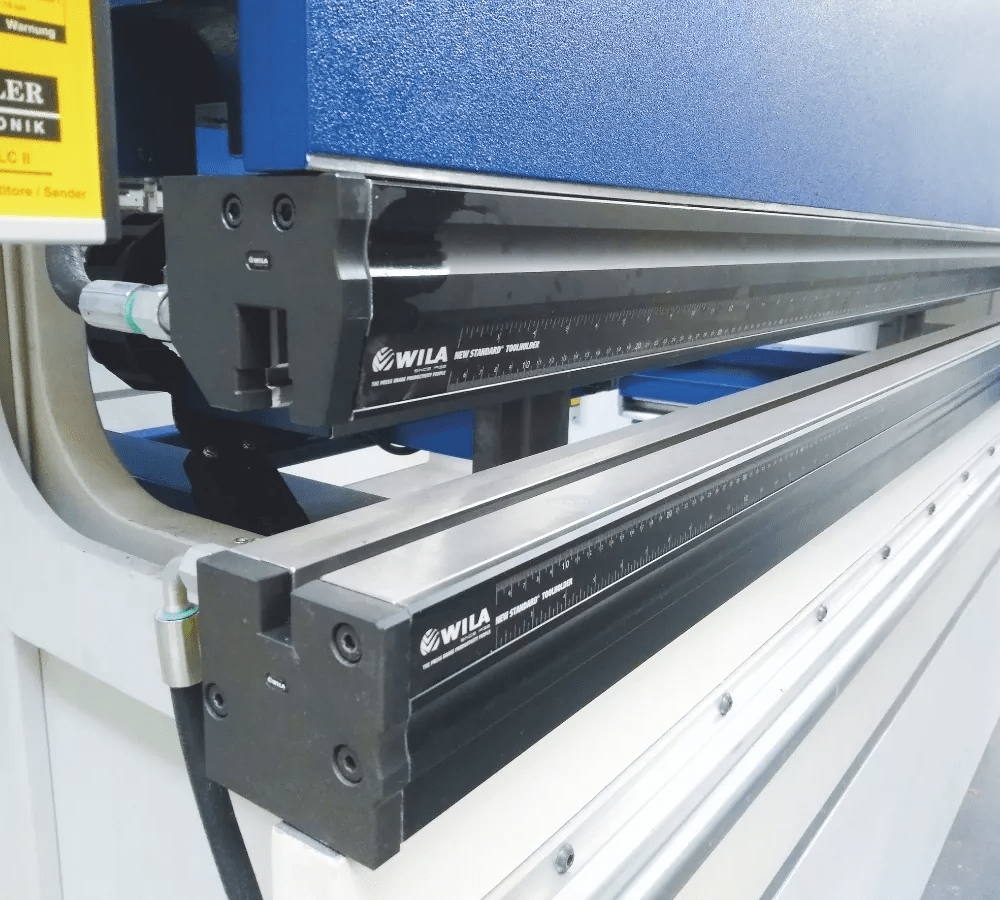

- Manual Anti-deflection crowning with original Wila wedges

- GIVI optic linear scales (Italy)

- Standard punch tools (H: 67, 85°, R:08)

- Standard die tools (4 Way Die =16-22-35-50mm, 85°, H:60)

- LED illumination on RAM

- Front laser safety

Available Options Include:

- Upgrade to 4-6 axis back gauge

- Deep throat

- Hydraulic oil temp control

- Manual/automatic lubrication

- Cabinet cooling

- Rolleri Rol200 hydraulic punch clamping

- Wila hydraulic punch clamping

- Wide bottom table for Multi Vee dies

- Motorized Anti-deflection crowning with original Wila wedges

- 1.000mm X axis travel

- Additional back gauge fingers

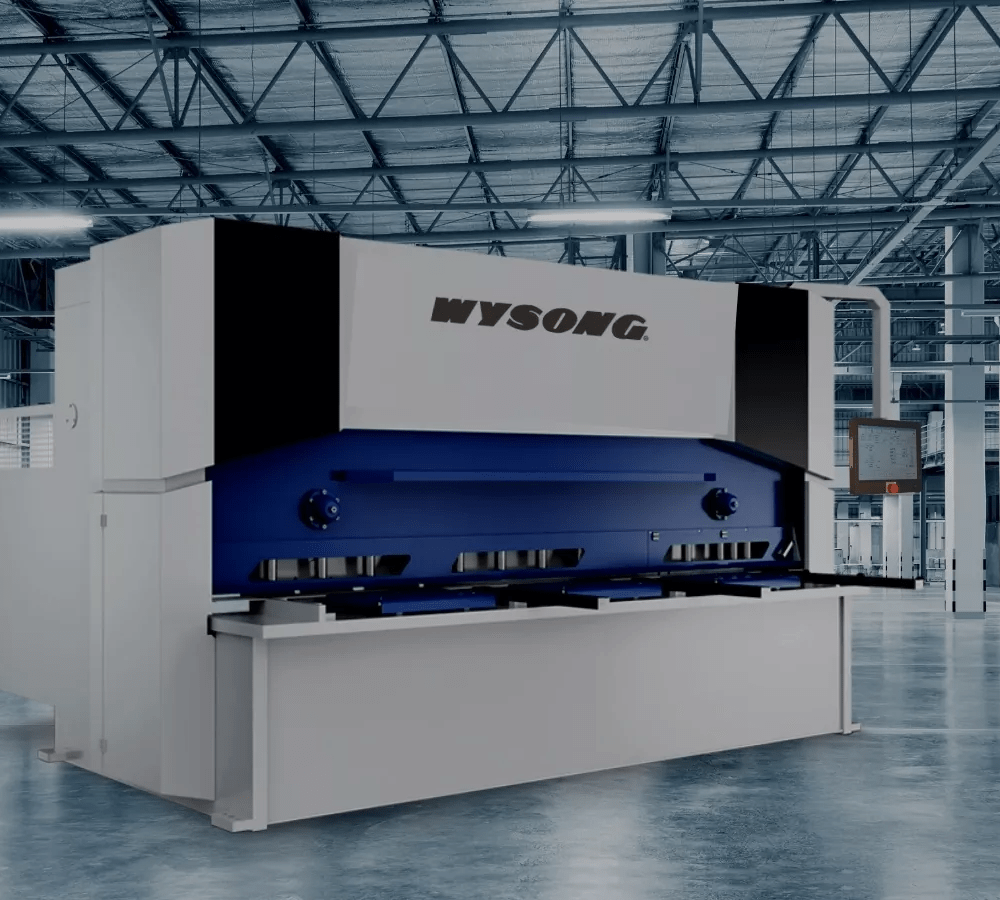

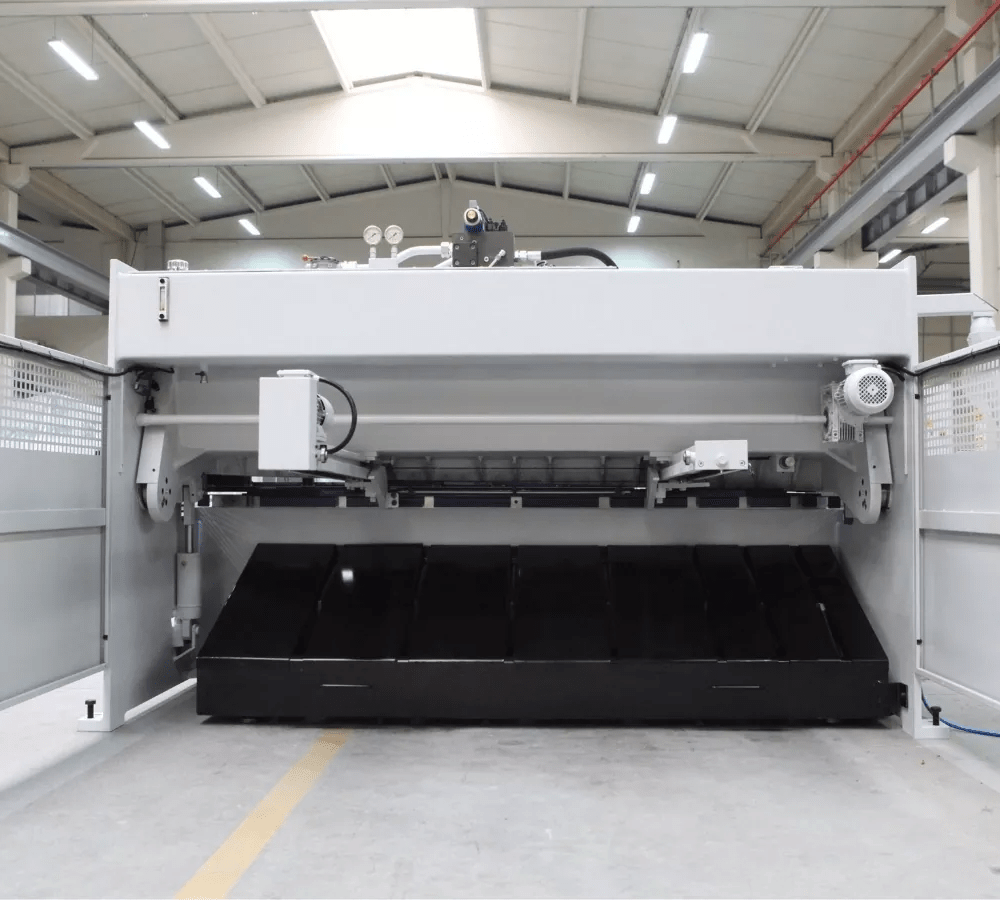

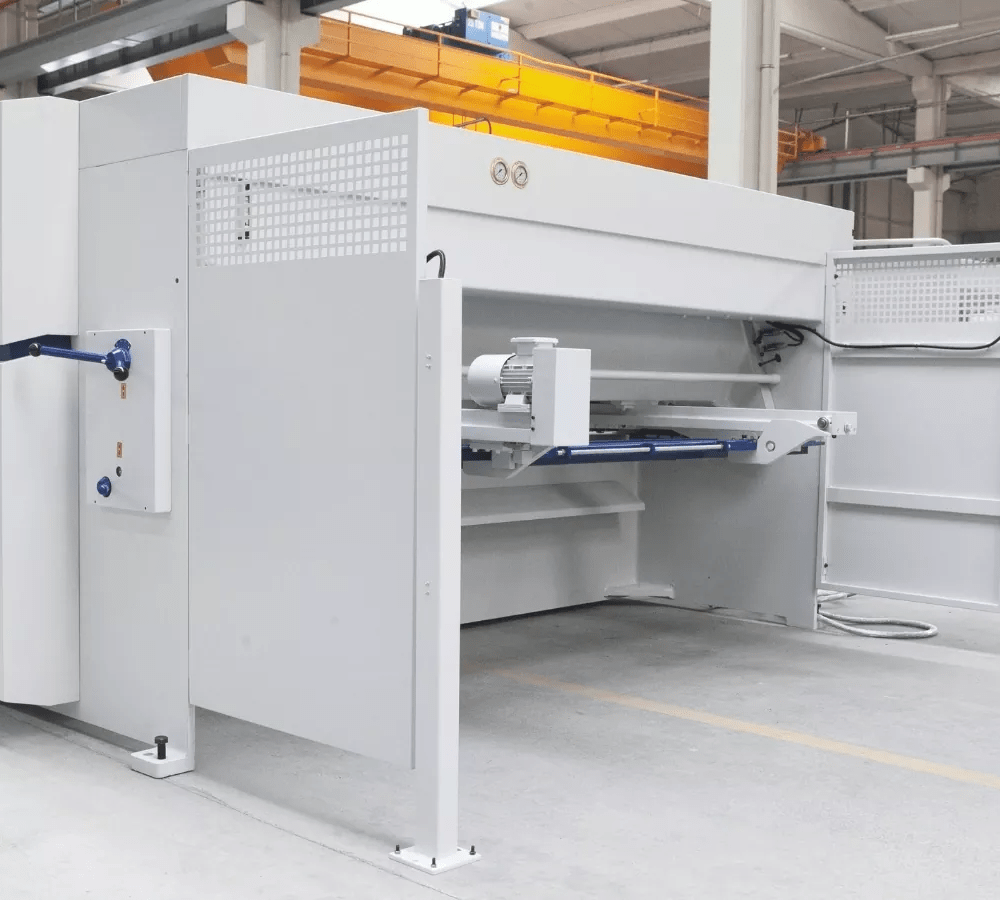

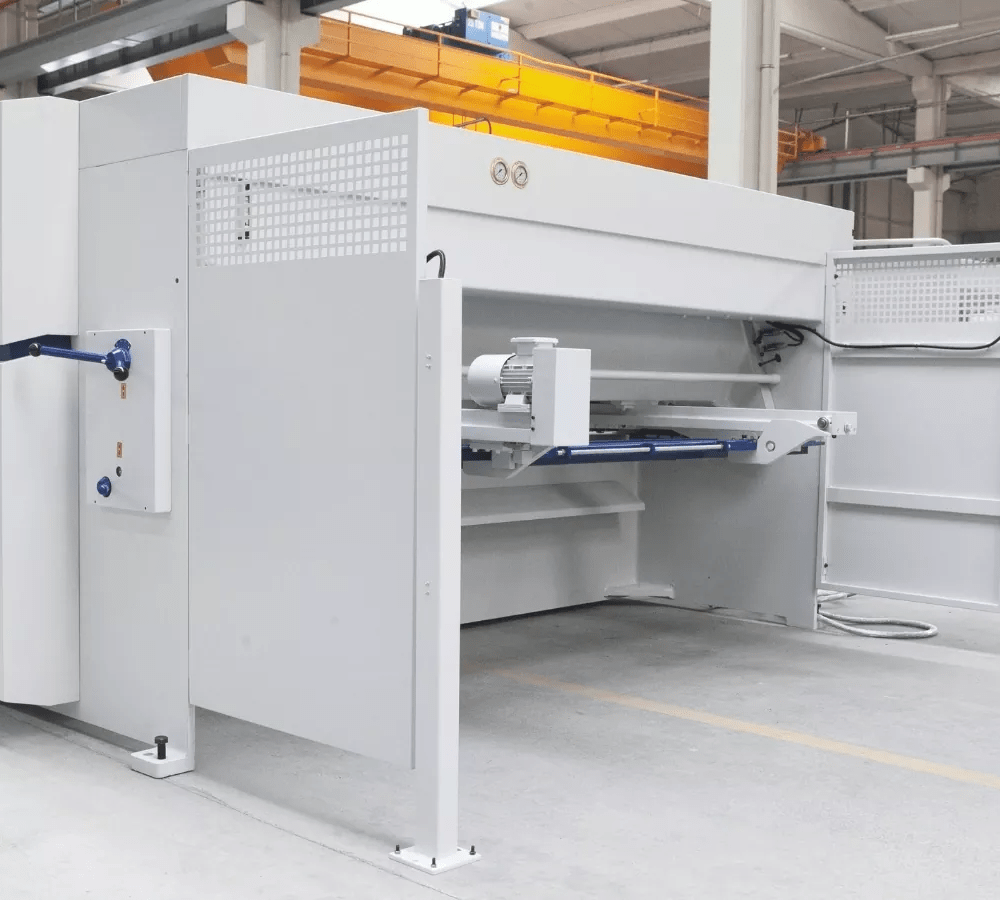

Hydraulic Shears

Wysong Hydraulic Shears are engineered to stand up to the most demanding production environments on the planet. Manufactured in Europe and supported by their industry veterans in the United States.

Standard Options Include:

- PC800 Shear Control

- Rexroth / Hoerbiger hydraulic system

- Manual blade gap adjustment system

- 39″ Programmable, motorized back gauge

- Double Speed cutting machine concept

- 9.84″ throat depth

- Programmable back gauge retract feature

- Back gauge swing-up feature for sheets longer than 39″

- Stroke adjustment for short cutting speed/efficiency

- Transfer table with roller balls

- Upper blade 2 edges / Bottom blade 4 edges

- 39″ front support arms with ruler scale, T channel & flip stops

- Front and side protective covers

- Illuminated cutting line

- Emergency stop buttons

- Front finger guard

- Foot pedal

- Special designed covers with movable controller arm

Available Options Include:

- Pneumatic Sheet support system (Type 1)

- Pneumatic Sheet support system- with front return to sender feature (Type 2)

- CNC controlled Auto blade gap adjustment system

- Angular gauge 0-180o

- Longer front sheet supports & squaring arm

- Special throat depth – 2x standard throat – 19.68″

- Full length opening front finger guard

- Laser guard for front finger protection

- Special alloy blades

- Laser cutting line

- Oil cooler and oil heater

- AC cooling unit electrical cabinet

- Automatic or Manual central lubrication

- CNC controlled front sheet feeder arms

- Rear laser barrier with CE conformity

Back Gauge Options Include:

- 2 Pos. Sheet Support

- 4 Pos. Sheet Support

- Rear Conveyor

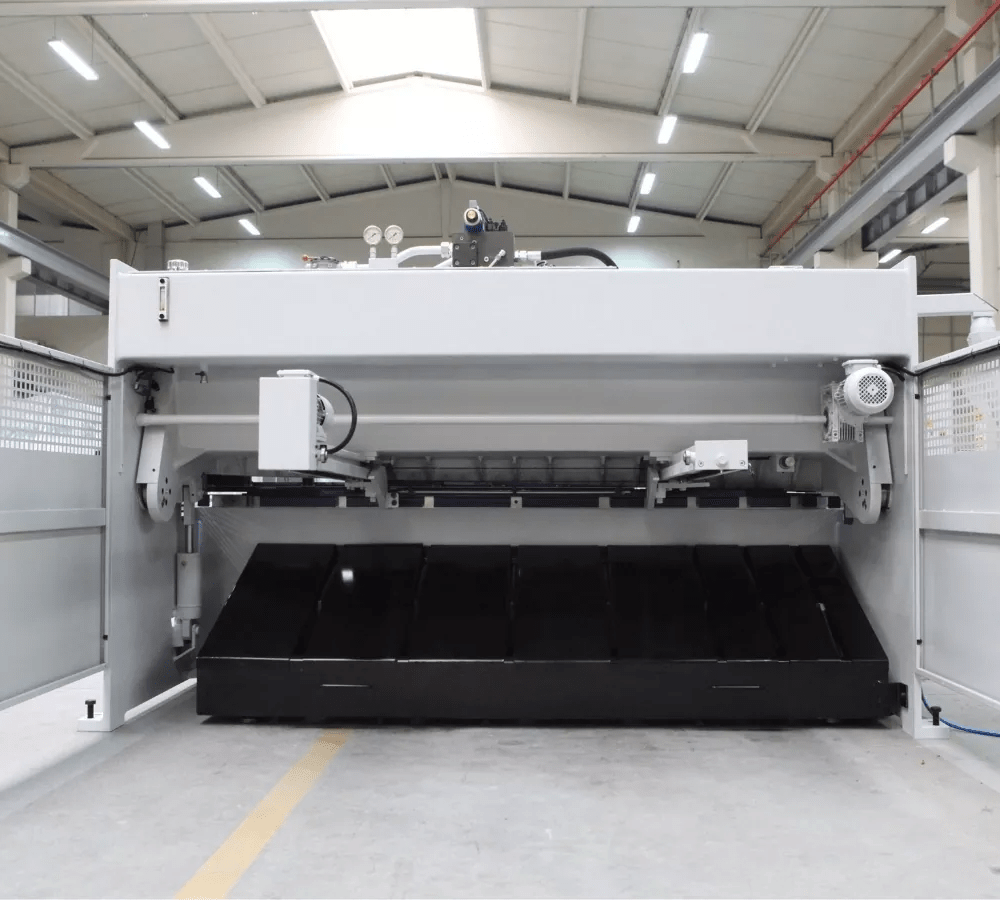

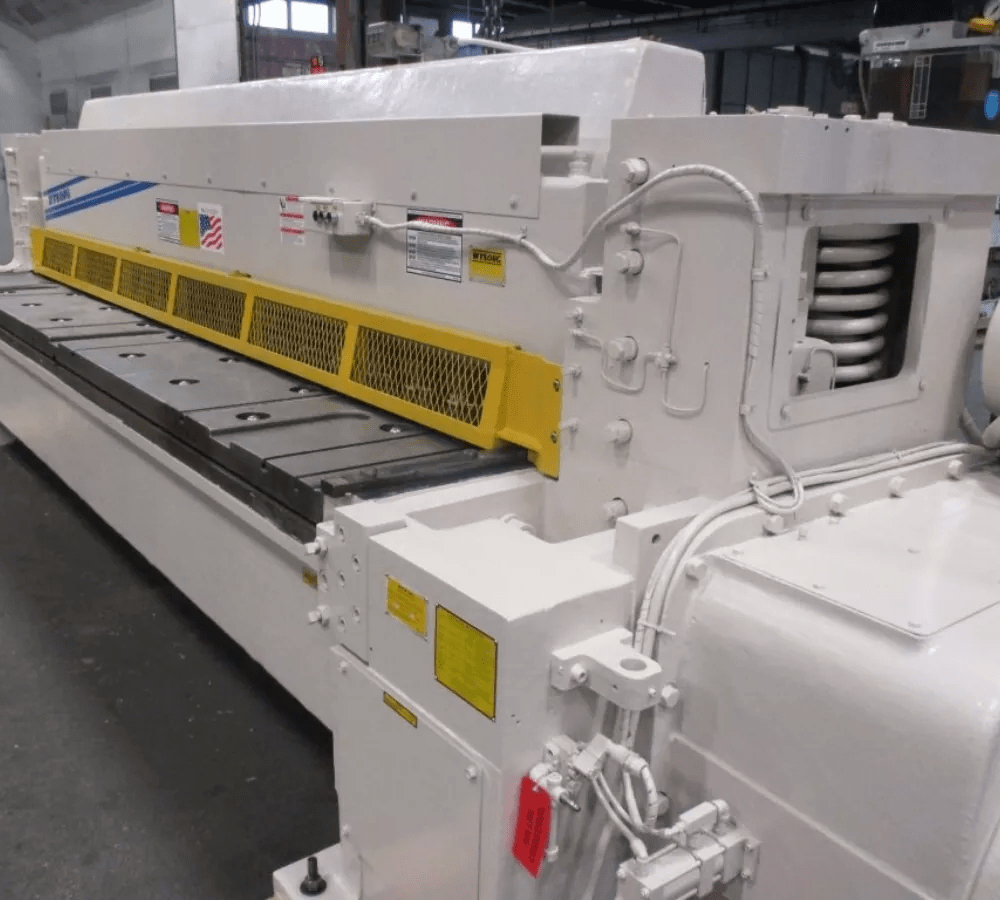

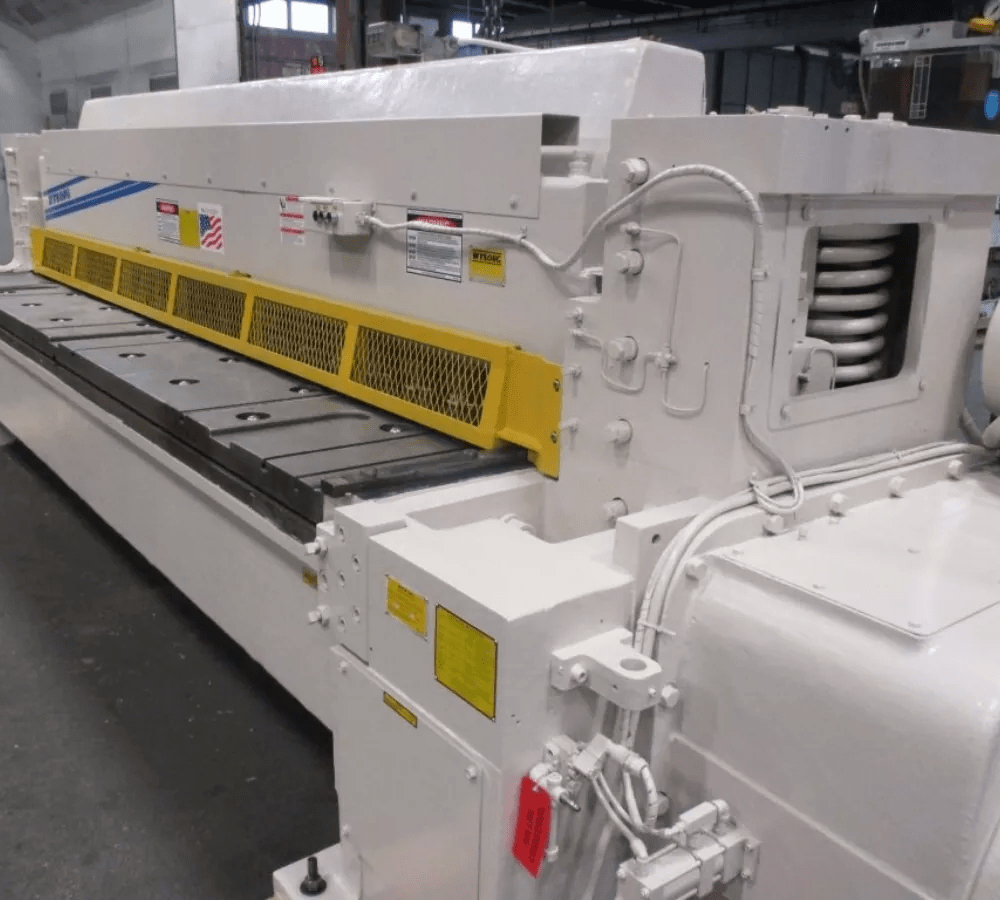

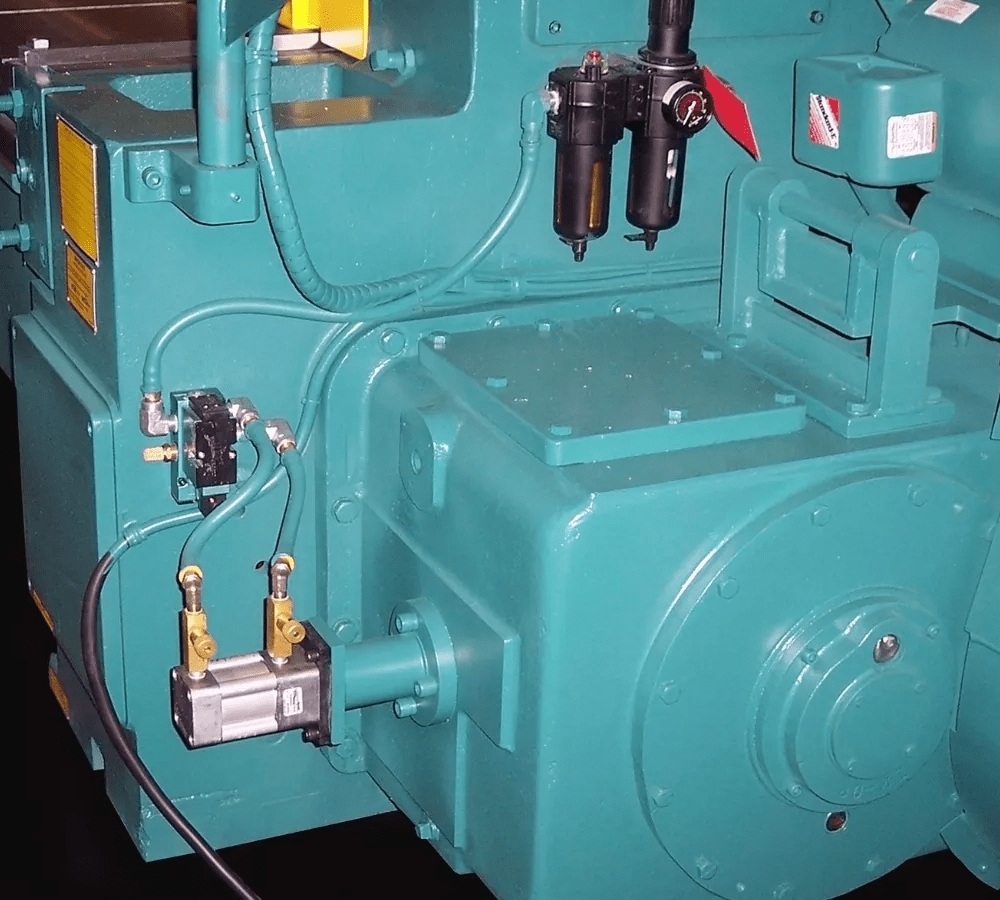

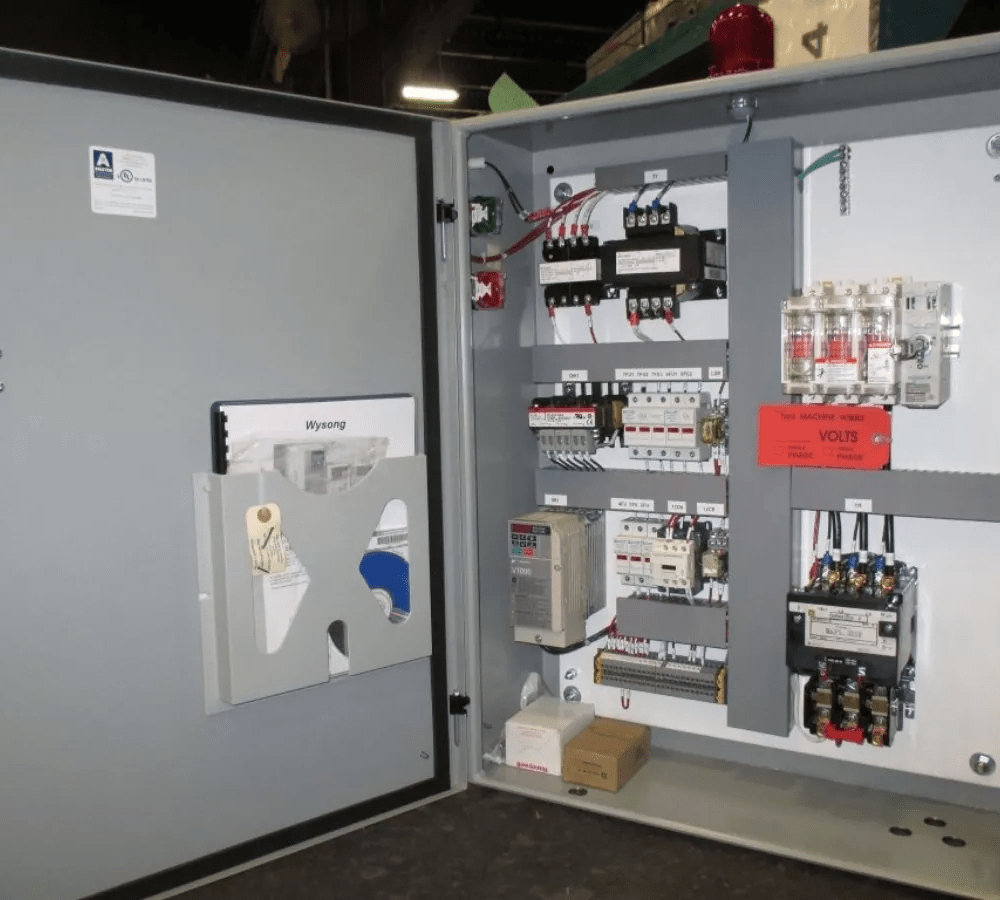

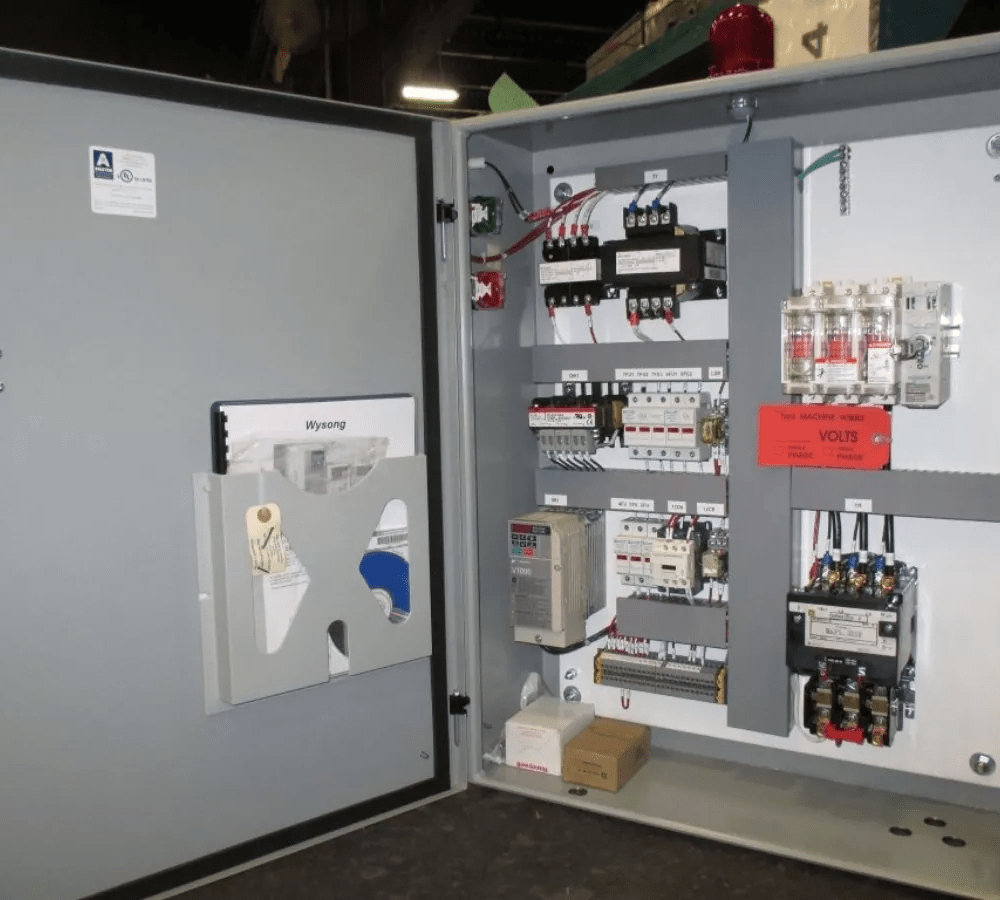

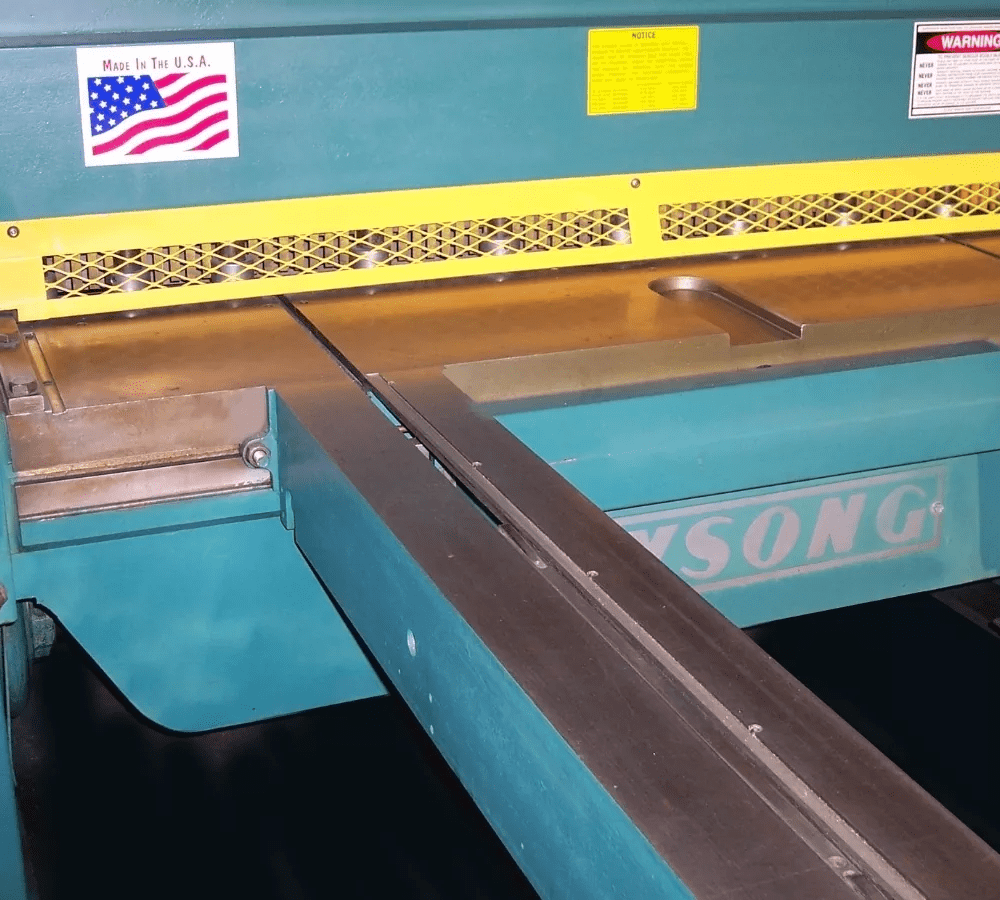

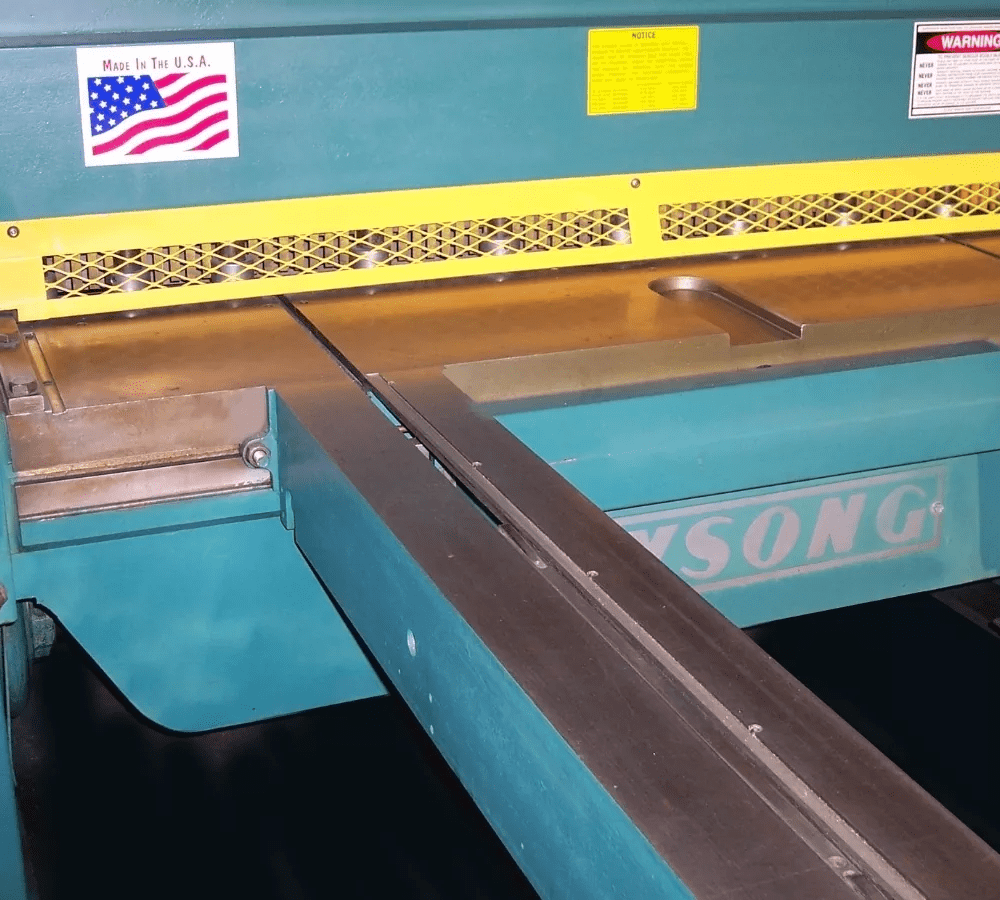

Mechanical Shears

The Wysong name has long stood for American-made machinery that is known for its near-indestructibility. Wysong mechanical shears are manufactured with pride at our 104,000 sf facility in North Carolina.

Standard Options Include:

- High tensile, ductile frame construction

- High tensile box style bed construction with reinforcing ribs

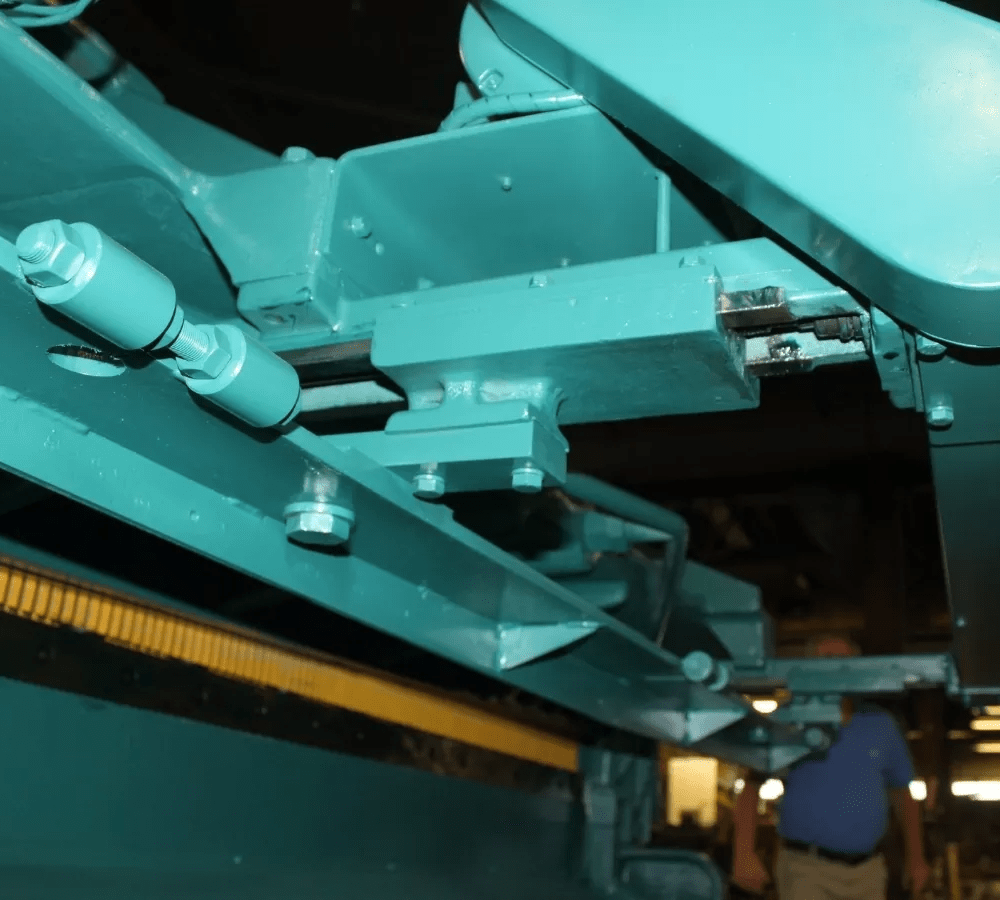

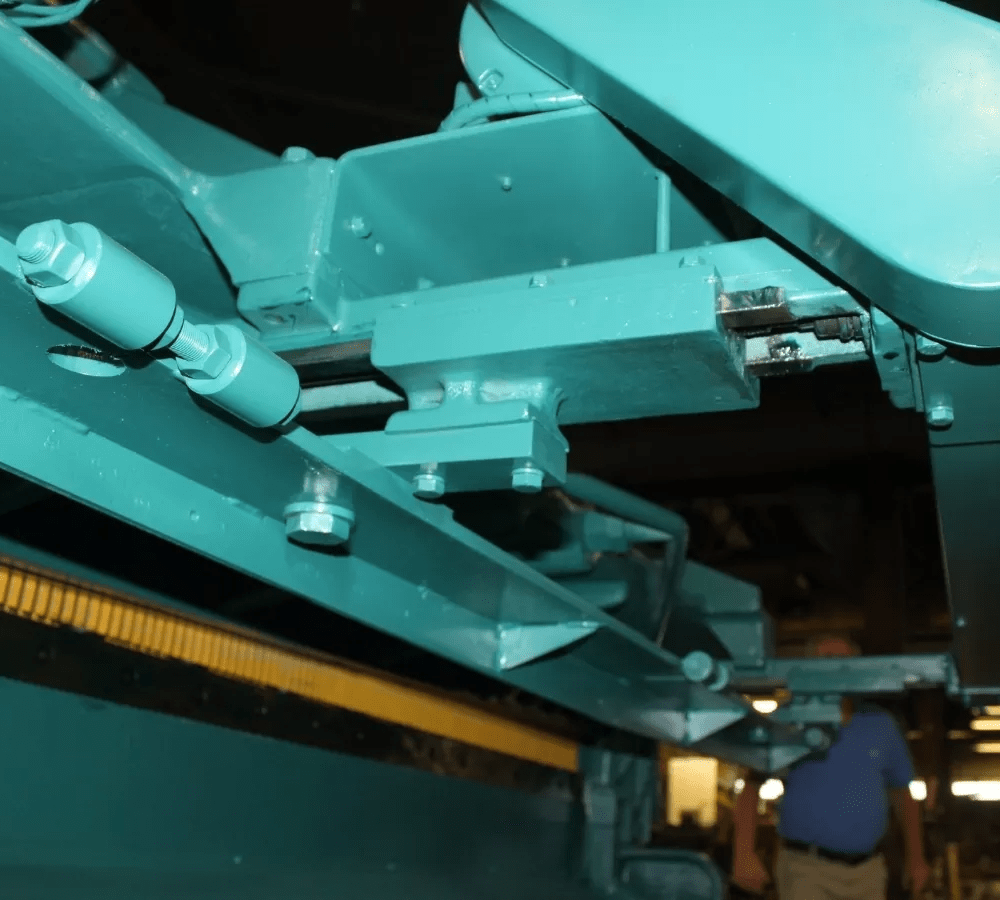

- T-shaped Ram construction with triangular reinforcing ribs to counter tensional deflection

- Ram is fully contained in oversized non-metallic gibing system throughout stroke length

- Adjustable, compensating, spring powered holddown

- Finger guard & barrier guard for operator safety

- Four edge, high carbon, high chrome blade (HCHC)

- 8-point blade adjustment

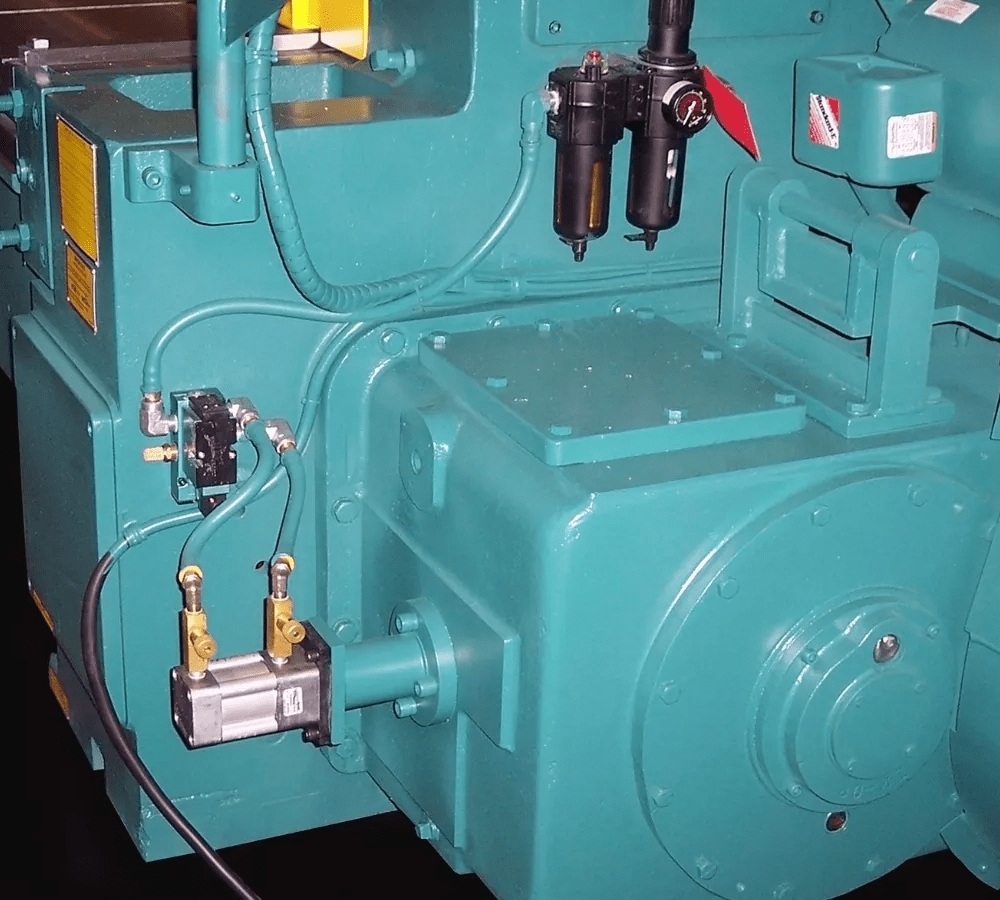

- Totally enclosed, vented transmission with oil bath lubrication

- Heat-treated nine jaw clutch system

- Cam operated spring set intermittent style brake

- Air filter and regulator

- Electro-pneumatic clutch control

- Remote foot switch

- 1800 RPM, 3 phase, 60 Hz, 230/460 motor

- 2-speed 24” range programmable data (36” standard for shears with ¼”+ capacity)

- +/- .002” positioning accuracy; +/- .001 reliability

- PC 800 control (up to 6-axis capability) for programmable control of back gauge, optional front and squaring arm gauges (servo driven)

- Unlimited seats of offline programming software

Available Options Include:

- Automatic oiler with safety cutoff

- 24″, 36″, 48″ range back gauge

- 6 ft. , 8 ft. , or 10 ft. squaring arm

- CNC front gauging

- Magnetic sheet supports

- Conveyor unit

- Conveyor/stacker unit

- Rubber hold down inserts for anti-marring

- LED Work lights

- Direct drive for increased speed and precision in cut-to-length applications

- Full length shoe-type hold down for cut-to-length applications

- Shear front extensions

- Custom paint colors

- Spare blades

- Electrical cabinet cooling for harsh production environments

Gauge Options Include:

- 24″ – 48″ Back Gauge

- CNC Front Gauge

- Conveyor/Stacker

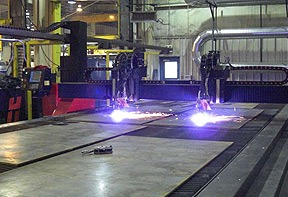

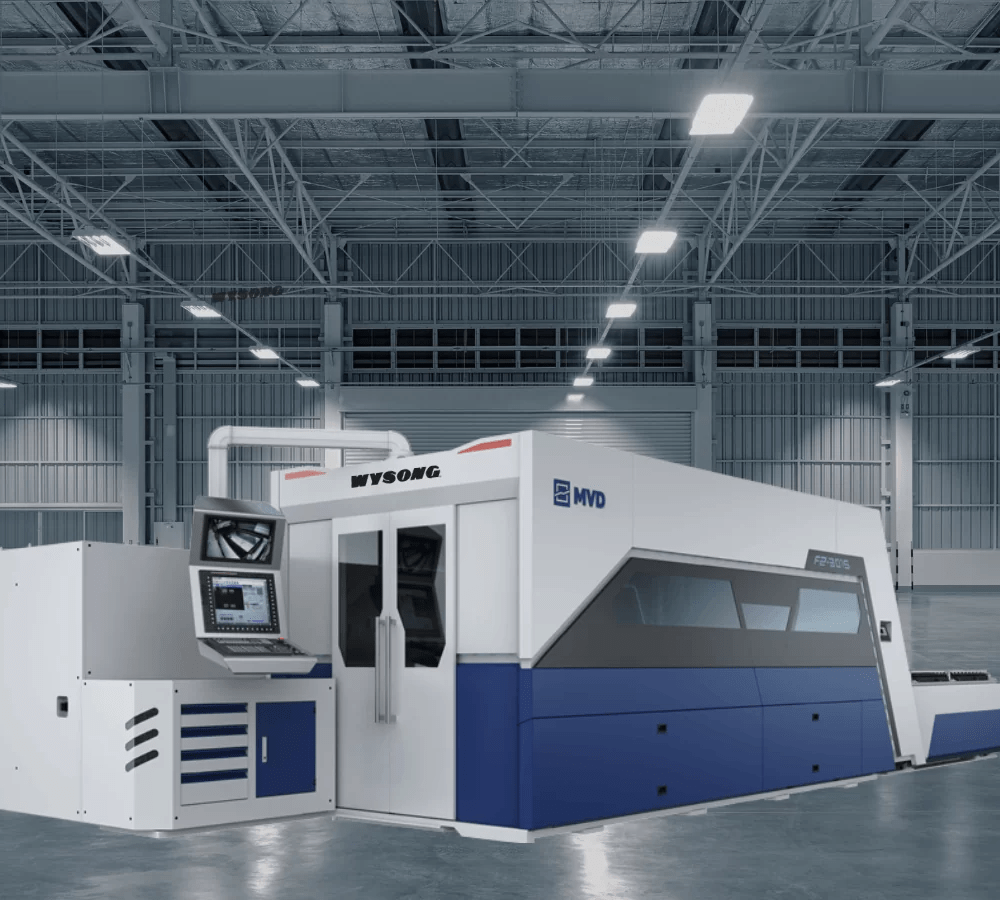

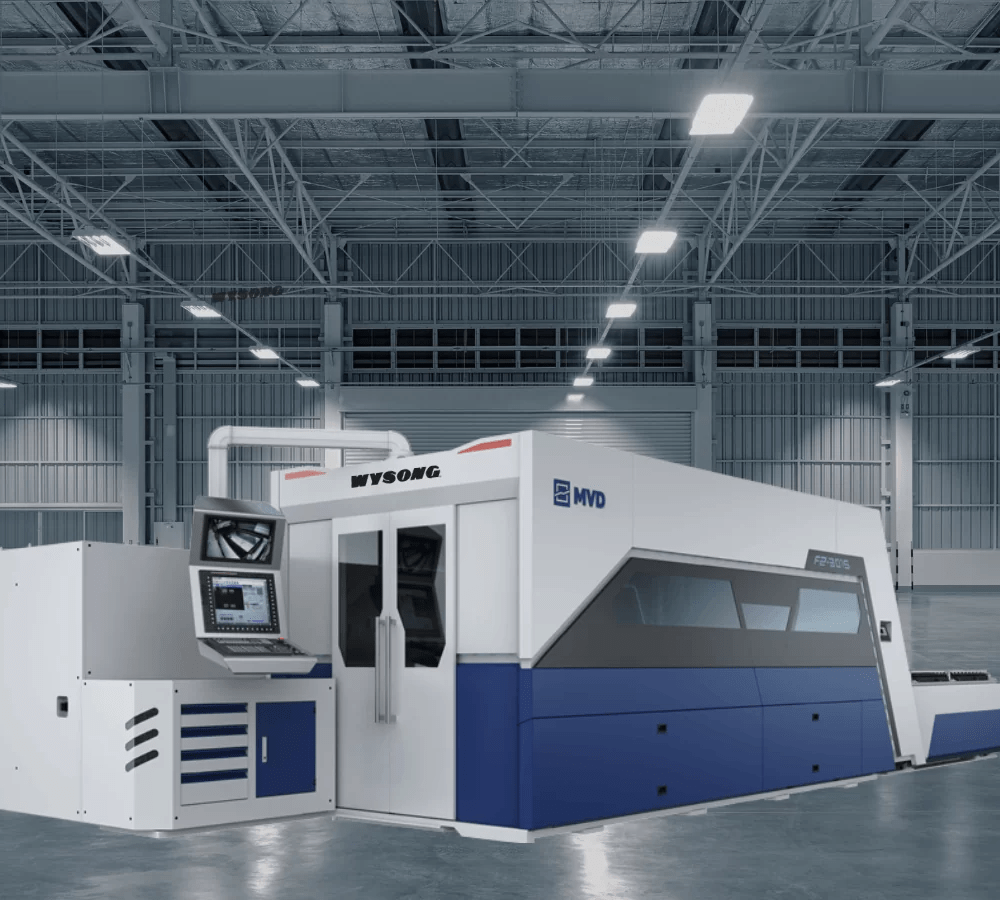

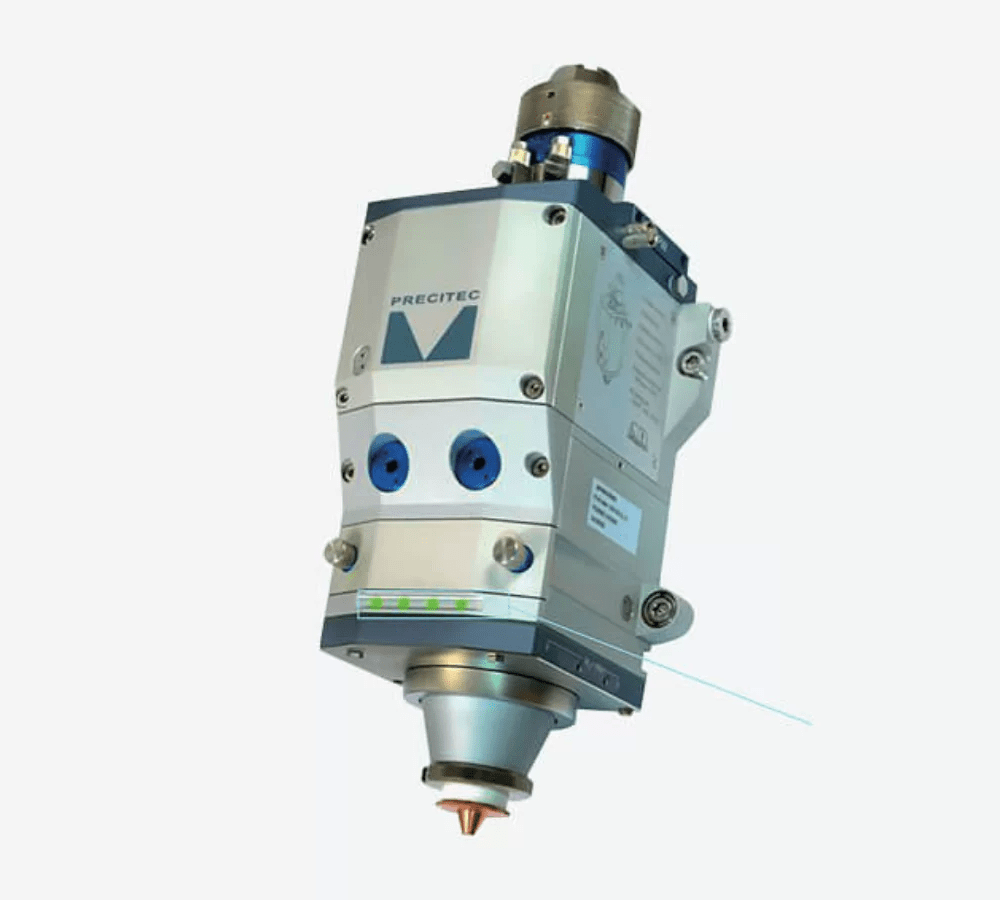

Fiber Lasers

Wysong MVD Fiber Lasers – Manufactured in Europe and equipped with best in class components. Built to Last.

Standard Features Include:

- Windows operating system

- Multi-touch graphic screen

- Multifunctional keyboard, button/joystick/speed potentiometer

- EtherCAT communications for data transfer or machine control

- Enhanced Database for cutting parameters, for different type

materials and thicknesses - Fly Cut functions for same direction high-speed cutting

- “No Piercing” technology for thin materials, efficiency time and

cost improvements - Better results at thick cuts, by prioritizing all piercings process before

regular cutting - Remote connection to PC

- Multi-language support

- Enhanced sheet metal recognition software

- Referencing and sheet alignment functions

- Setting different user-login levels for operators/maintenance/admin

- Multi-functional workpiece job order search/recall function

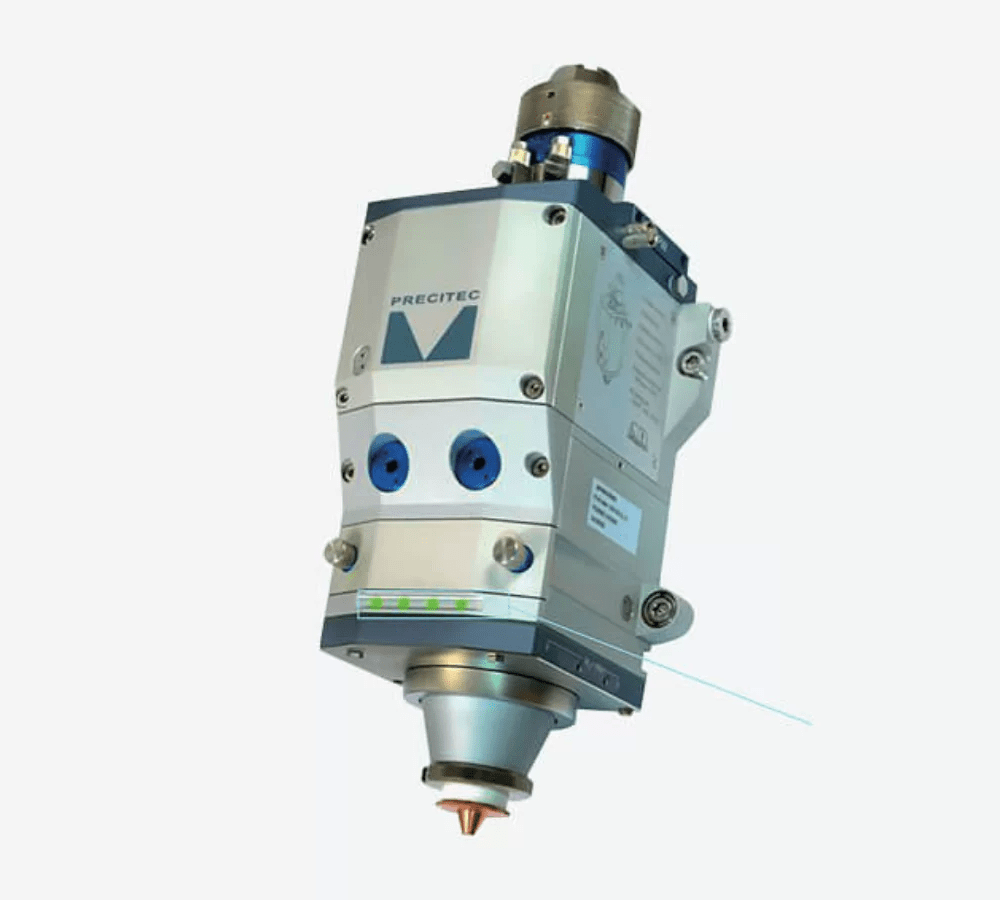

Components Include:

- IPG YLS Resonator

- Optimum focus diameter

- Maintenance free technology,

- Continuous perfect beam quality

with a laser beam is transmitted by the fiber core through the

fiber cable. - High efficiency, low consumptions of electricity fiber laser

technology, 5-6 times the lower running cost

- IPG Chiller

- Digital micro processing controlled industrial purpose chiller unit

- Part Nesting

- Lantek or Radan options

- Offers perfect nesting efficiency for automatic or manual part nesting

- Copy, move, reverse, turn alignment manual, semi-automatic,

functions geometrical working - Advanced nesting algorithm optimizes the use of material, minimizing scrap.