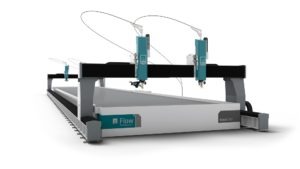

Flow Waterjet Cutting Systems

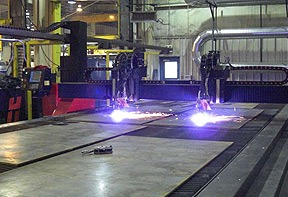

Innovative Waterjet Cutting Technology

Flow takes abrasive waterjet cutting to new levels of speed and performance. By combining precision system components, advanced pump technology and innovative software, they have created the most versatile waterjet technology available to manufacturers today. If you want to learn more about the need for a waterjet cutting machine, check out our blog post-Waterjet Cutting vs Laser Cutting!

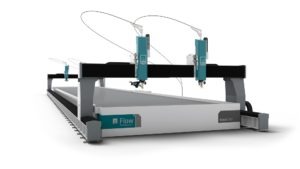

Waterjet Cutting Systems from Flow helps manufacturers maximize production with a few unique features.

- Direct Drive and Intensifier pump technology provides velocity where you need it which means you can produce parts faster and at lower costs.

- Patented Dynamic XD cutting heads, deliver accurate 5-axis motion, capable of cutting compound angles with high accuracy and giving programmers the greatest amount of flexibility.

- FlowXpert software allows quick programming and helps achieve the utmost in performance from the machine

- Most importantly, Flow machines cut parts fast, with some customers reporting cut times two to four times faster than their older machines

A Waterjet Cutting System Built For You

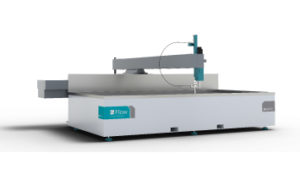

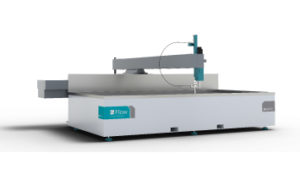

Flow waterjets are manufactured in a variety of lines adding to their ability to deliver a versatile machine to the end user. With different series, options, and sizes Flow can provide over 1000 different configurations to fit your specific application and need. Flow Mach 100 to Mach 700 and custom machines make Flow the market’s most versatile manufacturer of advanced waterjet cutting technology. Read below for a few of the machine series.

Mach 300 | Move Forward The Mach 300 is purpose-built to deliver reliable performance that you can depend on. The system is a no-nonsense waterjet solution that is efficient and practical. Combining advanced Flow waterjet technology into a small package, the Mach 300 minimizes impact on shop floor space – and your wallet.

A Pump for Every Application

There are two types of pumps used today for waterjet cutting: the linear intensifier pump and the rotary direct drive pump. Both intensifier and direct drive pumps are capable of reliably delivering ultrahigh-pressure water for heavy-duty industrial use in today’s manufacturing environment. Unlike the competition, Flow expands it’s portfolio by offering both types of pumps resulting in 1000+ sizes and configurations to offer customers.

A Pump for Every Application

There are two types of pumps used today for waterjet cutting: the linear intensifier pump and the rotary direct drive pump. Both intensifier and direct drive pumps are capable of reliably delivering ultrahigh-pressure water for heavy-duty industrial use in today’s manufacturing environment. Unlike the competition, Flow expands it’s portfolio by offering both types of pumps resulting in 1000+ sizes and configurations to offer customers.

- Rotary Direct Drive Pump

Rated up to 60,000 psi

The direct drive pump offers energy efficient, compact, and rugged design in a variety of configurations. - Linear Intensifier Pump

Rated from 40,000 psi to 94,000 psi

Flow’s intensifier pumps are the most technologically advanced ultrahigh-pressure pumps and are dependable and proven to deliver ultrahigh-pressure where you need it.

Flow Waterjet Software: FlowXpert

With Flow’s patented FlowXpert software, programming 2D or 3D models is simple, fast and accurate. With more intuitive programming your business will do more and make more with less effort.

- Import your 2D or 3D file or design your own from scratch

- Automatically clean up geometry issues

- Path your part, FlowXpert automatically creates the most efficient path

- Preview your part, the system will check for any cutting issues

- Save your ORD file and send to the machine, FlowCut does the rest

40+ years of waterjet expertise packed into easy-to-use software that is at your fingertips.

If you’re interested in learning more about Flow waterjets, or cut test parts on our showroom machine, contact us today to request a quote. We look forward to hearing from you!