How Mid Atlantic Machinery Automation is Combating the Machine Operating Labor Shortage

Mid Atlantic Machinery Automation (also known as MAMA), a robotic automation solutions company, was founded by employees of Mid Atlantic Machinery Inc., in order to “help small to medium sized shops compete globally by being able to implement affordable, versatile automation solutions,” (Joshua C. Mayse, Co-founder and VP of MAMA).

Since the global pandemic, labor pools for skilled manufacturing machine operators have been shrinking. Universal Robots reported that in March 2020, “finding and retaining a quality workforce was the #1 problem reported in a survey by the National Association of Manufacturers.” The challenge of fulfilling manufacturing roles is expected to continue, leaving an estimated 2.1 million unfilled jobs by 2030.

What are the Causes of the Labor Shortage in Manufacturing Machine Operating?

Consider these Statistics from Deloitte Insights:

- Manufacturers still have not recovered 41% of jobs lost to the pandemic

- 5 Million baby boomers are expected to retire from the manufacturing field within the next 10 years

- Finding qualified and skilled manufacturers is 36% harder than it was in 2018

With so many jobs being unfulfilled, and the low percentage of skilled workers available to fill the jobs, manufacturers are forced to hire people that do not posses the skills needed to fulfill the job. These issues are causing many organizations’ capacities to suffer – meaning that the increased production times, caused by a lack of skilled employees, is prompting manufacturers to put a halt on accepting new leads or to increase lead times of all projects.

While these statistics may sound like a threat to the manufacturing community, they also open the doors to creating new solutions and opportunities – one of these solutions being automation. In 2021, Deloitte’s study showed that “57% of manufacturing respondents reported using advanced technologies to redesign job tasks”.

Automation: The Future of Manufacturing

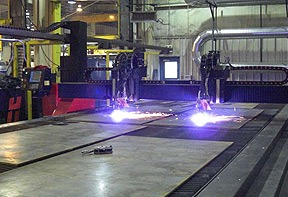

Mid Atlantic Machinery Automation aims to provide solutions to the previous stated issues by integrating robotic automation with classic machinery. Our team of professionals have created automated capabilities that provide flexible solutions to aid smaller shops as well as larger OEMs.

We manufacture our robots to ensure streamlined integration, along with a fool-proof user interface. MAMA’s products make it possible to seamlessly train and transition your current employees to automation, but it also widens the labor pool of potential new employees.

The labor pool shortage has proved to be very significant in recent years because baby boomers are known to be the most skilled generation of trained machine operators currently in the workforce, but they are headed towards retirement. Many younger workers have chosen to enter other industries, leading to the shrinking labor market for machine operators. The 2022 Career Interest Survey from the National Society of High School Scholars shows that STEM fields are among the top areas of studies for Generation Z.

It is important for the manufacturing industry to bridge these generational gaps. If automation is integrated into manufacturing now, once Generation Z is fully infiltrated into the workforce, the labor pool will grow with the possibility of hiring workers who are advanced in technology and engineering to run the automated machinery.

What Benefits Does Automation Provide?

MAMA has collaborated with the industry’s leader in collaborative robots, Universal Robots, in order to provide our customers with the best solutions possible. Our solutions ensure to manage labor shortage restraints while removing employees from performing unsafe tasks and creating a cost-effective, flexible, and safe robotics solution for a wide variety of machines in your shop.

Great Lakes Manufacturing recently purchased two automated solutions for press brakes from MAMA. In a recently conducted interview with Tom Demitras (Mechanical Engineer, Great Lakes Manufacturing), we learned that through integrating automation, the machine in use output 1,850 part in just one and a half weeks. It also helped to reduce program processing time by 90%. This machine was able to cut the company’s time and skilled labor needs, all while maximizing production output and optimizing ROI.

Automated machinery is the future. It is always improving and evolving. Our application engineers and robotic solutions team are continuing to conceptualize and advance our automation solutions to continue to provide our customers with unmatchable results.

How Can You Integrate Automation into Your Shop?

For more information on how you can future-proof your shop, explore the MAMA webpage, and contact us to speak with a robotics specialist and take the first step in advancing your business.